If you need, please feel free to contact us for more information. ③ Successful 10000+ customers across the globe

#REFLOW BGA SERIES#

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

#REFLOW BGA PROFESSIONAL#

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support. You must remember to bring the solder paste to room temperature and. This will make feasibility study on the effect of moisture content in the BGA component and its effect due to reflow soldering. Therefore, BGA component with ‘induced moisture’ via humidity test has been introduced as shown in Fig. Therefore, reflow BGA soldering equipment should be able to place a BGA package with an accuracy of +/-0.1mm. Reflow process is necessary to establish metallurgical interconnection between component and PCB. Special focus shall be paid to Stage-I, the Ramp stage to make ready the activation in the flux and Stage-4, the Time- Above- Liquidus, neither too long leading to de-wetting nor too short devoiding enough time for soldering to happen and formation of intermetallics. In addition, it is necessary to ensure proper alignment, as the solder joint of a BGA has a unique self-centering feature. If the BGA is RoHS appropriate Reflow profile shall be devised.

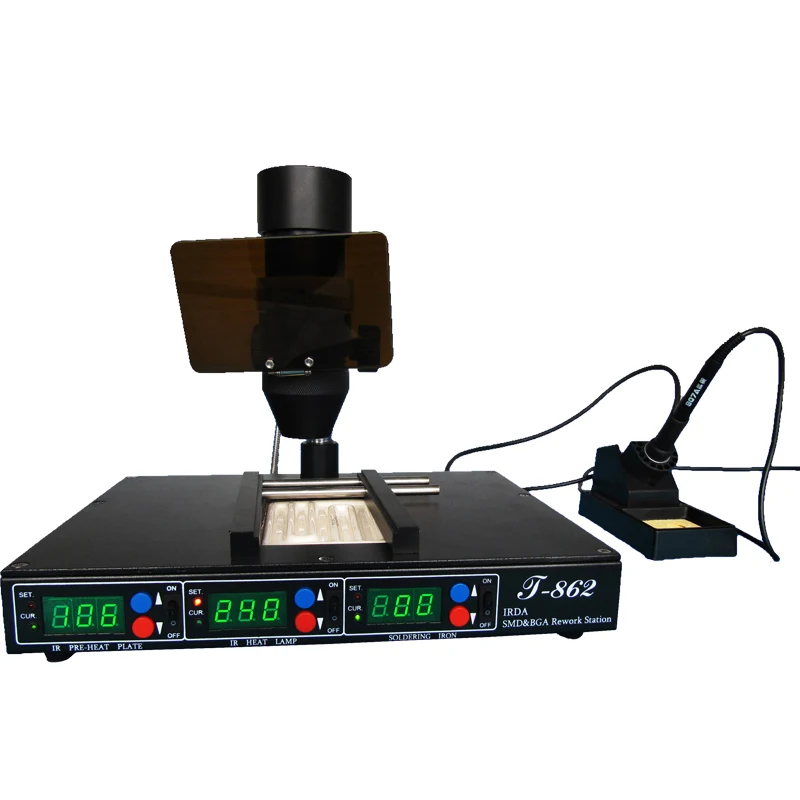

Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers. BGAs are very sensitive and require accurate alignment during the solder reflow process. Reflow BGA soldering equipment is essential for precision BGA placement. has been manufacturing and exporting various small pick and place machines since 2010. So we can send you the offer at the first time.įor designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.Ī: Usually we quote within 8 hours after we get your inquiry. Please provide the details of your requirements as clear as possible. Terrific For Through-Hole Connector Removal ZT-7 System Includes: Top Side Hot Air Reflow Station Bottom Side Powerful Preheat Adjustable PCB Holding Fixture. Provide one-stop SMT assembly production lineĪ: You can contact any of our sales person for an order. Intelligent, the custom developed intelligent control system, easy to use and powerful. Basically, our video shows reflow at the top of the joints and then part separation. Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.Ĥ. Heat insulation protection design, the casing temperature can be effectively controlled.ģ. 1. High-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature deviation is significantly reduced compare to the similar reflow oven products in the market.Ģ.

0 kommentar(er)

0 kommentar(er)